Nissan Altima (L32) 2007-2012 Service Manual: P2138 APP Sensor

Description

The accelerator pedal position sensor is installed on the upper end of the accelerator pedal assembly. The sensor detects the accelerator position and sends a signal to the ECM.

Accelerator pedal position sensor has two sensors. These sensors are a kind of potentiometers which transform the accelerator pedal position into output voltage, and emit the voltage signal to the ECM.

In addition, these sensors detect the opening and closing speed of the accelerator pedal and feed the voltage signals to the ECM. The ECM judges the current opening angle of the accelerator pedal from these signals and controls the throttle control motor based on these signals.

Idle position of the accelerator pedal is determined by the ECM receiving the signal from the accelerator pedal position sensor. The ECM uses this signal for the engine operation such as fuel cut.

DTC Logic

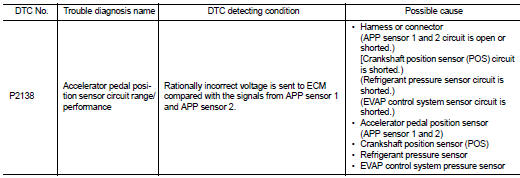

DTC DETECTION LOGIC

NOTE: If DTC P2138 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to EC-867, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 8V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Go to EC-936, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E9. Refer to Ground Inspection in GI-45, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK APP SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position (APP) sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between APP sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or shot to power in harness or connectors.

3.CHECK APP SENSOR 2 POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ON.

2. Check the voltage between APP sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 4.

4.CHECK APP SENSOR 2 POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between APP sensor harness connector and ECM harness connector.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit or short to ground or shot to power in harness or connectors.

5.CHECK APP SENSOR 2 POWER SUPPLY CIRCUIT-III

Check harness for short to power and short to ground, between the following terminals.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair short to ground or short to power in harness or connectors.

6.CHECK COMPONENTS

Check the following.

• Crankshaft position sensor (POS) (Refer to EC-786, "Component Inspection".) • EVAP control system pressure sensor (Refer to EC-824, "Component Inspection".) • Refrigerant pressure sensor (Refer to EC-975, "Diagnosis Procedure".) Is the inspection result normal? YES >> GO TO 11.

NO >> Replace malfunctioning component.

7.CHECK APP SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between APP sensor harness connector and ECM harness connector as follows.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair open circuit or short to ground or shot to power in harness or connectors.

8.CHECK APP SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between APP sensor harness connector and ECM harness connector as follows.

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair open circuit or short to ground or shot to power in harness or connectors.

9.CHECK APP SENSOR

Refer to EC-938, "Component Inspection".

Is the inspection result normal? YES >> GO TO 11.

NO >> GO TO 10.

10.REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Go to EC-938, "Special Repair Requirement".

>> INSPECTION END

11.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

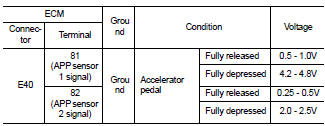

1.CHECK ACCELERATOR PEDAL POSITION SENSOR

1. Reconnect all harness connectors disconnected.

2. Turn ignition switch ON.

3. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Go to EC-938, "Special Repair Requirement".

>> INSPECTION END

Special Repair Requirement

1.PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

Refer to EC-565, "ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Requirement".

>> GO TO 2.

2.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Refer to EC-565, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement".

>> GO TO 3.

3.PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-566, "IDLE AIR VOLUME LEARNING : Special Repair Requirement".

>> END

P2135 TP Sensor

P2135 TP Sensor P2A00 A/F Sensor 1

P2A00 A/F Sensor 1